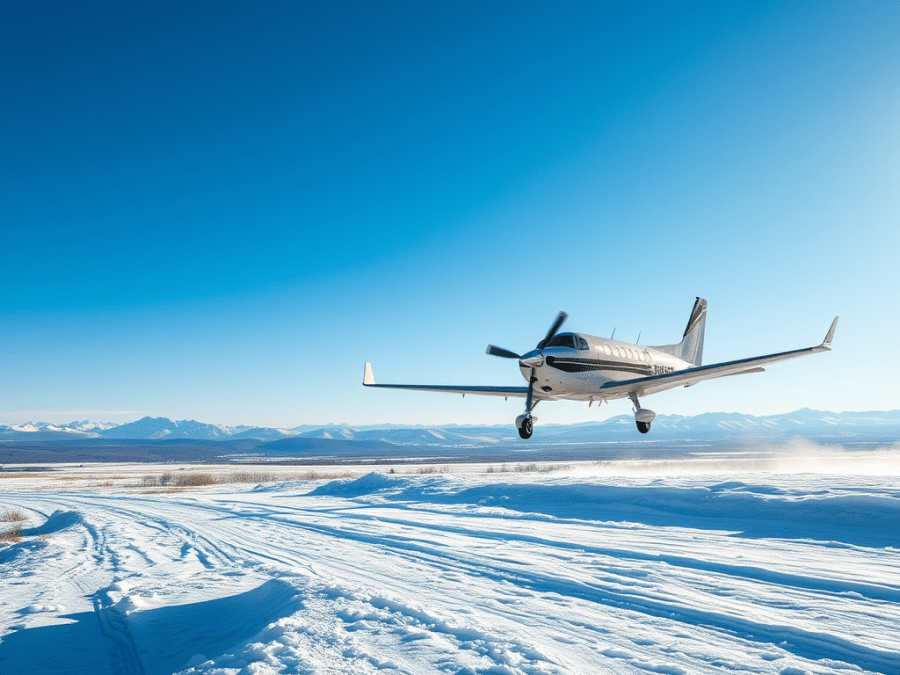

The new year brings fresh flying adventures and a resolution to fly more during winter, regarded as a great season for flying due to cold, dry air. Various monthly fly-ins and upcoming events offer opportunities to socialize and enjoy winter flying experiences, featuring breakfasts and attractions across different locations.