The Early Years

I first started flying my Model II Kitfox in September of 1991. At the time of building, I had two engine options: a Rotax 912, which produced 80 hp, or a Rotax 582. While the 582 only produced 65 hp, the performance numbers for the plane were approximately equal due to the lighter weight of the 582. The major drawback of the 582, of course, was that a two-stroke engine used more fuel to produce the same cruise speed.

When it came time to actually choose an engine, I reckoned that the substantially lower price of the 582 would permit me to buy a lot of fuel with the money not spent on the substantially higher-priced 912. I installed the 582.

After accumulating approximately 80 hours of flying time on my new airplane and engine, I departed on one of my most memorable flights ever. Using a flight plan speed of 70 knots, I traveled from Airdrie to Summerside, Prince Edward Island, and back again. As you can imagine, at this speed the journey required many fuel stops. Because the Kitfox was so new to everyone at that time, curious onlookers caused flight delays at almost every landing. During my stop at Thunder Bay, one of the tower controllers actually asked me to please wait until he got off shift so he could come and see the airplane!

A Family Milestone

Another thing that made this trip most memorable was that I got to take my father for his first-ever airplane ride! When I told him I was building an airplane, he was a bit skeptical, unsure that he’d ever want to go for a ride in it. However, he conceded that if I could fly the Kitfox from Calgary to Toronto, it should be safe enough for him to take a ride. I was able to overfly the family farm where I grew up, located on the south shore of Lake Simcoe.

It was an experience of a lifetime for Dad to be able to see his farm from the air. The Model II has now accumulated approximately 1,200 hours of flight time. While it was slightly neglected over the past several years, my son Ken and I have both been flying it occasionally. In 2008, I finished building my second Kitfox, a Model 5 equipped with a Lycoming O-235.

On my 80th birthday in 2019, I had another very memorable flight: I was able to fly in formation with Ken flying the Model II while I flew the Model 5. Not many people can say they flew in a father/son formation in aircraft they built themselves, let alone on their 80th birthday.

The Yamaha Conversion Project

In retirement, one needs to keep busy. In addition to skiing and golfing, I need an ongoing project. Over the past years, I’ve read various articles about people having great success converting Yamaha snowmobile engines for aircraft use.

There were three models being converted: the Phazer, the Sidewinder, and the Apex (two, three, and four-cylinder engines, respectively). Unmodified, these engines range in output from 80 to about 160 hp. I decided to replace the 582 in the Kitfox II with the 80 hp Phazer engine.

I estimated I could put a relatively new engine in the airplane for around $10,000. The project started with the purchase of a Yamaha Phazer snowmobile as a donor. I actually operated the snowmobile at the Airdrie airport for a while to get a feel for the engine’s characteristics. I noted that the engine really started to develop power when the RPM got up to about 8,000.

Engineering and Electronics

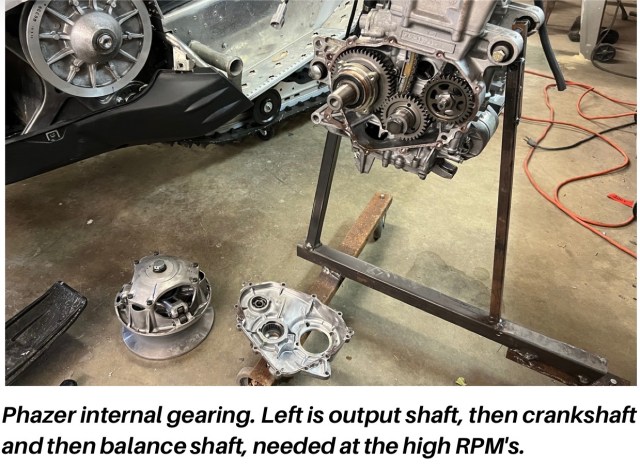

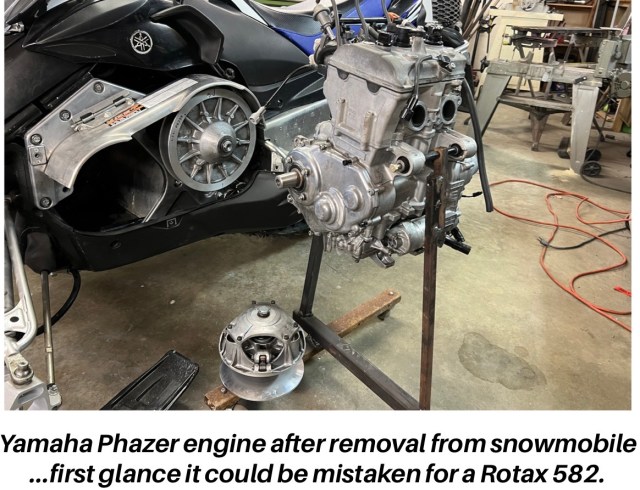

Removal of the Phazer engine and its associated wiring was a bigger project than I expected. Once the engine was out, it appeared very similar in size to the 582. It is a four-stroke, 80 hp engine with approximately 600 cc displacement. However, while the 582 maximum RPM is 6,800, the Phazer can reach 12,000!

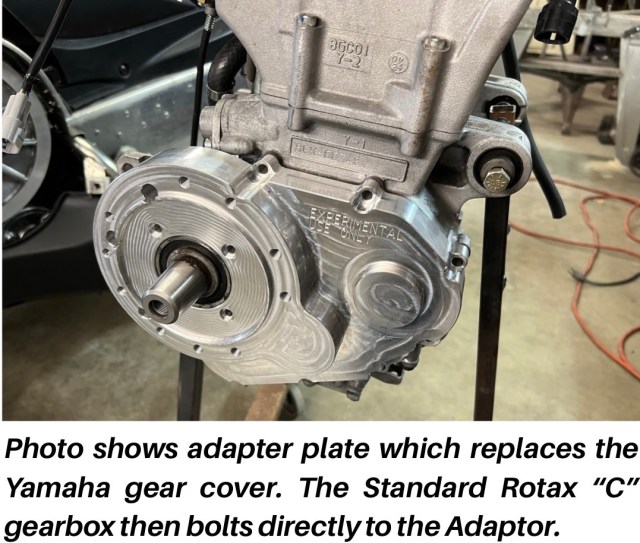

I transferred the gearbox from the 582 to the Phazer using a built-in gear reduction on the output shaft. This kept the propeller rotation the same, allowing me to use my original prop. I also added a centrifugal clutch for easier starting and an electronic sensor on the prop hub to read propeller RPM directly.

The electronics were a challenge. I had to “fool” the computer into believing the transmission was in gear to allow the engine to rev up. My RCAF training in electronic circuit diagrams was essential here. I also had to fabricate a custom motor mount by creating a plywood “firewall” mock-up and fitting steel tubes one piece at a time.

Troubleshooting and Results

Once moved to Kirkby Field for test flights, I hit a snag: the engine would not exceed 8,000 RPM. I rebuilt the exhaust system and replaced ignition coils, but the issue persisted. As a last-ditch effort, I removed and cleaned the fuel injectors. This turned out to be the solution to the entire frustrating problem!

The engine now performs beautifully. While I don’t have final numbers yet, the climb rate appears slightly better than with the 582, and I expect fuel consumption to be about half of what the Rotax used.

The project took 18 months—three times longer than my initial estimate—and cost about $13,000. There were many times during testing that I wished I had never started, but now that it is running correctly, it feels like a true accomplishment. Only time will tell if it’s really been worth the struggle.

very cool , I like the way you think. I am considering it also.. the Yamaha phazer will put out 90 to 96hp though. You need to get rid of the air box and put in 2 or 1 K & N air filters this will ad 4 to 7hp and use Suzuki sidekick headers chopping off 2 of the tubes. Have them jet hot coated the end will run 60degrees cooler then throw a adjustable fuel pressure regulator and a power commander controller 3 or 5 if you can find 1 they allow you to up the fuel and spark. They really do work and I’ve seen dyno sheets with this set up. It will allow you a gain in gas mileage also by 10%

LikeLike