“More maintenance is necessarily better”

I recently came across an article by Mike Busch that was in EAA’s March 2011 issue of Sport Aviation.

In this article Mike talks about reliability-centred maintenance (RCM) and how maintenance programs were developed for high levels of safety and performance. He points out that RCM is performed in all segments of aviation except the lower end community of General Aviation (think Cessna, Pipers, etc) versus the corporate business sector of GA.

Research done in the 1960’s showed that the premise of time related “useful life” reliability was wrong. The RCM thought process included new thinking that included the following points:

- Most failures were not age-related but were either infant mortality or maintenance induced

- Changing efforts to manage failures

- Change from fixed-interval and time-directed to on-condition maintenance

- Removing the most TBO’s and life limits to condition monitoring

- Recognize that most components, systems failures have acceptable consequences and run-until-it-breaks is acceptable

This shift in maintenance thinking resulted in massive reductions in maintenance costs and downtime with an unexpected dramatic reduction in in component failures and downtime.

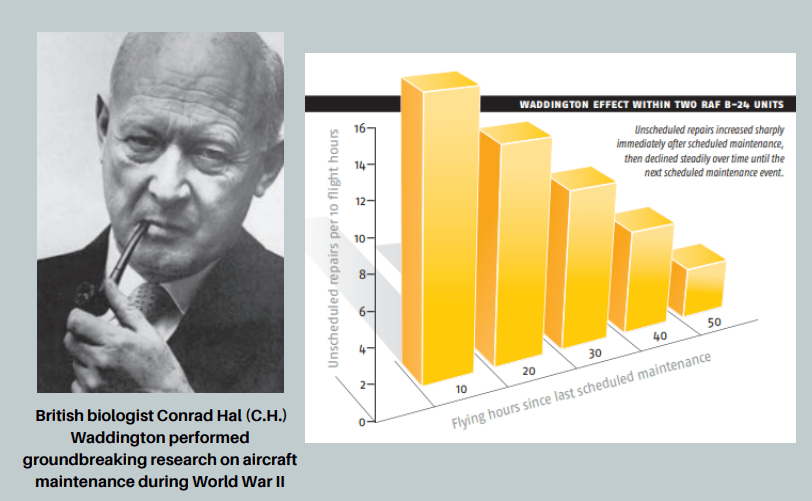

While this appeared to ground breaking research at the time (1960’s) it was actually a British scientist, Conrad Waddington, who, during the Second World War investigated the maintenance and breakdowns of the RAF bombers.

When his Operational Research (OP) team reviewed the data on scheduled and unscheduled maintenance they found some very surprizing results: Unscheduled repairs increased sharply after each scheduled maintenance event (50 hours) then declined steadily until the next scheduled maintenance event when they spiked again after the maintenance.

The OP Team conclusion was that scheduled maintenance tended to increase breakdowns by “disturbing a relatively satisfactory state of affairs” and there was no sign that the breakdown rate was increasing after the mandatory scheduled maintenance interval had been exceeded. In fact the observations demonstrated that scheduled maintenance was actually doing more harm than good. It was dubbed the “Waddington Effect” in a paper written by Prof. James Ignizio in 2010.

Revisions to the RAF maintenance program included:

- Increase time between scheduled maintenance events

- Eliminated maintenance tasks that were not deemed beneficial

- Improved maintenance personnel scheduling

- Create better maintenance guidance and documentation

The recommendations and subsequent revisions to the maintenance program resulted in a 60% increase in bomber fleet flying hours – a very substantial improvement.

So how does this translate into our GA fleet? Well, we now can run our engines beyond the recommended TBO period and operate “on-condition” until the performance, etc dictates action is required. Most of our engines will give us indications as to their general health and performance but we have be familiar with their normal performance parameters.

Simple maintenance such as checking spark plugs, compression, oil consumption, etc are all part of the engine health monitoring program. A friend of mine who flies turbine aircraft told me that a turbine will generally give no indication of failure until it does whereas a piston engine will almost always “talk to you” before failure – if you are listening!

It’s also a common saying that the first five hours or so after a scheduled maintenance event are the most dangerous and have the most failures. That‘s not just a saying – there are quite a number of incidents right after scheduled maintenance. These can be as simple as forgetting to put oil in, controls hooked up wrong, lack of safety wiring, etc.

Maybe sometimes it’s better to fly until its breaks! Just make sure that you and your aircraft safety is not compromised by any potential failure.

Here’s the link to the Mike Busch article

Enjoy the read!

Mike Busch Profile:

Mike Busch, EAA 740170, was the 2008 National Aviation Maintenance Technician of the Year and has been a pilot for 44 years, logging more than 7,000 hours. He’s a certifi cated fl ight instructor and an A&P-IA. E-mail him at mike.busch@savvyaviator.com. Mike also hosts free maintenance webinars on the first Wednesday of each month at 8 p.m. (Central). To sign up or access the archives, visit www.SavvyMX.com/webinar