Over the course of flying my Cavalier through the few days in March that were available to me, I realized that the Cav had an oil temperature issue. This wasn’t a huge surprise, but it was frustrating.

The first day I flew the new engine the outside air temperature (OAT) was about 5 degrees C and the oil temperature was steady at about 205 degrees F. This was a bit troubling because the O-290’s oil never exceeded 200 F except on the warmest days, and even then, not by much. Was the high oil temperature the result of a new and tight engine, or was there a more intrinsic heating problem with the Cav’s cowling and oil cooler set up?

After landing on the first flight the oil cooler was cold, as were the lines leading to it. It was either an airlock in the system because we hadn’t filled the lines or the cooler with oil prior to running the engine, or the cooler was simply blocked.

Ken Vike, my engine over-hauler, said there should be enough ambient pressure from the engine to fill the cooler and force any air through. He also made a good point in saying that the cooler might contain a bunch of gunk from the old engine that I didn’t want circulating in the new one. I tried unsuccessfully to find a place here in Calgary that flushes oil coolers. I ultimately decided that the Cav deserved a new oil cooler after more than 30 years, so I ordered one.

After installing the new cooler, I flew the Cav on a day with an OAT of 10 degrees C but the oil temperature was now up to 220 degrees F. This wouldn’t do.

Time to start the investigation in earnest and solve the mystery of why the oil temps were so high. First things first. I confirmed with a digital thermometer that the gauge was reading correctly. I also confirmed that the engine was pumping oil through the cooler.

But a closer look at how cooling air was getting to the cooler revealed a possible villain.

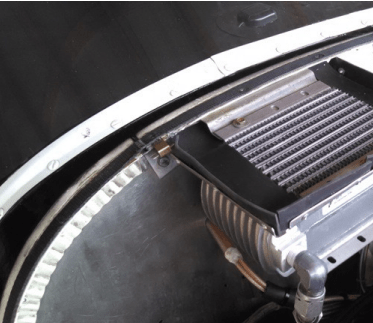

The Cav has a cowling that slopes downward from the front of the wind screen to the prop. In the top of the cowling is a set of louvers that capture air and direct it into the top of the cooler. But there is a space of about 3/4 of an inch between the cowl and the cooler that allows air to run past the cooler itself. I decided to build a shroud that would attach to the cooler and capture and forcefully direct all the louvered air through the cooler. I also confirmed the cooler is well vented on its bottom side.

Incidentally, the entire cowling exit is a good size, too, so that cooling air over the cylinders also exits well. However, a closer look at the baffle on the front right cylinder showed me I could add a bit more there to ensure proper cylinder cooling and alleviate any hot spots. In fact, my cylinder head temps are only about 300 degrees, again confirmed with a digital thermometer. I built the oil cooler shroud using scrap aluminum and baffle seal rubber.

Here’s a photo of it:

I test flew this arrangement on a day with an OAT of 5 degrees C and saw a reduced oil temperature down to about 195 degrees F. That showed promise and that my problem solving was probably headed in the right direction.

Thus encouraged, I decided to continue my efforts to force more cooling air through the oil cooler. The best way to do that would be to build an air scoop that would capture and pressure air directly into the louvers feeding the cooler.

I experimented with a template I fashioned from construction paper and settled on a set of dimensions that would fit. I made the scoop from aluminum and bolted it on using AN wood washers for backing on the bottom side of the cowl. I was quite pleased with the result and think it looks a bit like a hot rod part.

Here is a photo of the scoop fitted in place without any mounting hardware:

I flew the Cav with the scoop installed on a warm spring day with an OAT of 15 degrees C. I was quite happy when the oil stayed steady at 190 degrees F. So far I’d shed about 30 degrees of excess oil temperature. The Sherlock Holmes approach was really starting to pay off.

No investigation of engine cooling would be properly complete without checking the Vernatherm, which is essentially a thermostat in the oil system. My research indicated that oil in the 320 circulates oil through the engine AND through the cooler at temperatures below about 180 to 190 degrees F. When the oil hits 180 to 190, the Vernatherm expands and seals off the port that allows the oil to bypass the cooler. Thus expanded, the Vernatherm sends ALL the engine oil through the cooler. I pulled the Vernatherm plug from the oil filter housing and learned I didn’t even have one.

This obviously isn’t catastrophic at all, and some engines don’t even have a Vernatherm. A quick call to Vike Aeromotive and I had one in hand the next day. I installed it and went flying on a day that varied from 5 degrees to 10 degrees C, but through it all the oil only got up to 180 degrees F for a few minutes. The rest of the time it stayed steady at 170.

This may be a mixed blessing because I’m not sure if the Vernatherm actually operated. My suspicion is that it opened near 180 degrees and because the oil temperature only dropped by about 10 degrees, it wasn’t enough for the Vernatherm to return to its cold setting. Thus it stayed expanded and forced the oil exclusively through the cooler. Of course, the cooler now has so much more cooling air being scooped up and rammed through it to remove the excess heat. All tolled, I’ve shed an astounding 50 degrees of oil temperature.

By way of performance changes, here’s what I’m seeing in my Cavalier. The IAS has increased by a minimum of 10 knots to 120 knots, which works out to just shy of 150 mph TAS. Climb is at about 1500 fpm. Fuel burn is about 7 gallons per hour running hard at 2550 rpm or more, due largely to the electronic ignition.

As spring creeps it’s way into the Calgary area the days will get warmer. That’s when I’ll see if the cooling arrangement works as I hope it will. But at this point, I’m pretty sure that the oil cooling mystery has been solved. I also want to eventually add a couple more inches of pitch to the prop, but that will mean a different prop all together because my current one is pitched as high as it can be.

With the oil temperature mystery solved, and longer days ahead I can now focus more tightly on breaking in the engine and enjoying the reliability and longevity the new O-320 will provide for my Cavalier. There are a lot of airborne adventures out there waiting for us.