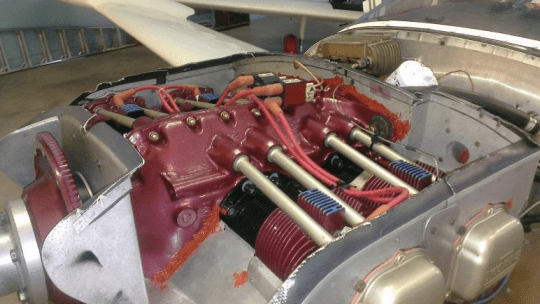

In mid-February I In mid-February I drove to Kamloops, BC to pick up my engine from Vike Aeromotive. Once I found Vike’s shop, I spent a very enjoyable hour with him discussing engines and airplanes and looking around his shop at the various engines under construction or repair. Then we loaded my newly overhauled and shiny purple, gold and black painted O-320 into my vehicle.

Two days later I set about the task of attaching it to the front of the Cavalier. Naturally, I wasn’t alone in this endeavour. Gerry MacDonald had volunteered his services, and Bob Kirkby once again offered up space, heat and light in his hangar to enable the job to be done comfortably and efficiently. I couldn’t have done this job without their help. Gerry is an experienced airplane owner who does as much work on his plane as he can, and that experience really shows through in all that he does around airplanes.

As we slid the hoisted engine into place on its new mounts Gerry noticed that two of the engine mounting bolts were noticeably worn with smooth gouges that had been worn into them over the 31 years since the Cav started flying. That was a full stop, and it meant a nearly week-long delay while Aviall got the bolts in. Turns out I got four of the last six left in their entire system.

The following Saturday Gerry and I were back at it. We got the engine mounted and started re-attaching things that were sticking out of the firewall. Fortunately, the dimensions between the 290 and the 320 are nearly identical. That helped most of the time, but there are still some things that are quite different between the two.

There were only a few changes that arose during the install, and even those were quite minor and easily rectified. Things like the air box support bracket, routing of the oil cooler lines, and the exhaust bracing all required little adjustments.

Watching Gerry work was a real treat. He was rarely stumped by anything, and he accomplished each task quickly, efficiently and with the highest quality. I sometimes felt embarrassed when I was struggling with a seemingly simple task while he was progressing steadily through everything he did.

This was most apparent with the baffling. The 320’s size and shape are just different enough to make the baffles a bit of a challenge. I had a fair amount of difficulty with the baffle chores that I worked on. Obviously, the baffling has to be done correctly to effect proper cooling. What made those chores so difficult was the Cav’s tight cowling and the slightly different shape behind the prop hub.

Finally, on the first Saturday in March, the 320 was ready to test run. Gerry wisely suggested that we run it first with the cowling off for a few minutes. This would make it much easier to check for leaks and squeaks before we cowled it up again for flight.

We rolled it out into a bright chilly morning and pointed it into the wind. I climbed in and latched the door. I went through my pre-start checklist and turned the key. Nothing caught on the first few blades, but by the third or fourth it did catch and started running.

A number of things competed for my attention; a low and satisfying whine, ironically similar to a turbine; the engine’s noticeable smoothness, and the fact there was no oil pressure yet. Lycoming allows 30 seconds without oil pressure registering, but I saw the needle start moving at about 12 or 13 seconds. That was a huge relief.

I spent the next several minutes with my eyes glued to the instruments and my ears tuned for anything sounding amiss. Gerry braved the icy propwash to check for anything dripping or wobbling that shouldn’t have been. I ran the engine up to 1900 rpm and everything seemed great. I gently pulled back the throttle and allowed the engine rpm to descend to about 350 or 400 rpm before I finally pulled the mixture. The low idle would need adjustment, but we’d cleared a major hurdle.

We fastened the cowling back on and went to lunch. This was partly because I was hungry, and partly because I wanted to take my time before I flew the plane. It turned out to be a welcome break and the weather improved during the time we were away from the field.

Upon returning, I climbed in and started up again. Two things had yet to be done; the static run up and the mag check, which I’d forgotten to do when we ran it naked. I wanted to minimize any low rpm taxi time, so as soon as I could I had the Cav headed for the button of Kirkby’s runway 34. Once there I did my standard mag check and was quite relieved to see we had timed the electronic mag perfectly.

Now it was time for the static rpm check. This was the part I was most concerned over. I worried that the prop, a Sensenich 74 x 58, would be grossly underpitched. A conversation with Ken Beanlands taught me a lot about why prop pitches differ for the same engine on different aircraft models. Generally, speaking, the prop is pitched to match the performance of the airframe as much as the engine. Thus, planes that use the 150 hp Lycoming and the same 74″ diameter as mine might have pitch ranges from 54 to 62 depending on aircraft performance. I needed to look for an airplane that had similar performance to what the Cav would have behind the 320.

My research turned up the Grumman Cheetah/Traveller, which also uses the 320-A2B. It’s prop numbers are almost identical to mine, and its performance is pretty near what I thought the Cav would show. Maybe my prop worries would be for naught.

I set the brakes and eased the throttle to full. Just as I saw about 2450 rpm the tail came up sharply, surprising me. Worried about a prop strike on my brand-new engine, I released the brakes, and we started rolling. But the extra torque was ahead of me, compounded by the right crosswind. The acceleration was substantially higher than with the 290, too. Things were starting to get ahead of me and it scared me for a second.

I refused to let that happen. I stabbed the left rudder, tracked to the centre line and quickly got the Cav back under my control. In seconds the Cav and I we were finally flying again. The climb rate was predictably excellent, exceeding 1000 feet per minute without even trying. All temperatures were in the green.

I spent the next hour staying close to Kirkby’s in the event I needed to land quickly, but no major issues arose. Carl Foreman was on the ground with Gerry and his partner, Barry Wood. Gary Abel and Geoff Pritchard took video and photos. Carl reported on the radio that the engine sounded just great.

Despite my anxiousness upon first committing to flight, within half an hour I noticed a very comfortable relaxation setting in. I was still very aware of the Cav and what could go wrong, but nothing was going wrong. I was enjoying my beloved airplane once more. I landed after 60 minutes with a big grin and a lot of relief.

We checked the engine over carefully but could find nothing amiss. The only difficulties that arose in flight were high EGT readings, which I’m pretty sure is due to a mismatch between the guage and the new probe; and the oil temperature sitting at about 205 degrees. Not dangerous at all, but we did learn that the engine oil is not making it to the cooler. Gerry and I suspect an airlock, and we have a solution we’ll apply as soon as we can.

The prop is in fact under-pitched, but only by a little. It’s easy to keep it well within safe limits. I’ll likely acquire another, coarser one later on, but it doesn’t need to be a priority right now.

I flew another 1.2 hours that day running the engine hard, at well above 2550 rpm. It’s crucial to run the engine as far above 75% power as you can. This forces the rings to seat properly against the cylinder walls which is essential for engine longevity. I was gratified when checking the oil upon my second landing to see that hardly any was gone in the second hour of flight. I think I’m doing something right.

After 2 1/2 months on the ground, I’m glad to be back in the air with the Cav. It feels right flying with this engine, and it’s much smoother than it was with the 290. I’ve gained 10 knots in cruise, maybe a bit more, but my fuel burn has increased, too. At the high RPMs it’s burning just less than 8 gallons an hour. It should really be higher, but the Lightspeed Plasma electronic ignition makes a noticeable difference.

The really hard work is done now, thanks very largely to Gerry MacDonald’s efforts and Bob Kirkby’s generosity. I now get the fun of completing the breakin and then seeing just what the Cav will do with an extra 25 horsepower under the hood. I really am the lucky one.