Over the course of the last several months of flying my Cavalier I saw a substantial increase in oil consumption on the plane’s Lycoming O-290D. There turned out to be a number of causes.

First there was a lack of oil-air separator, which, combined with a less than ideally routed crank case vent hose, allowed some of the engine oil to fall overboard. There was also a loose and leaky valve cover on the #1 cylinder. Carl Forman, Bob Kirkby and I repaired that during the formative stages of a three-day long snow storm that stranded us in Gillette, Wyoming on our trip to Washington, DC last September.

Upon returning home I added an oil-air separator, and I did note a slight decrease in oil consumption. Though still well within limits, it remained higher than it should have been. I consulted my favourite AME, Ken Beanlands, who indicated the problem my well lay in a worn valve guide. This, he explained, would allow oil to enter the combustion chamber and deplete the oil level more quickly.

I took the Cav to Jon From’s Cloud 9 Aviation in Red Deer, since Ken lacked the proper tools to confirm his diagnosis, and learned the prediction was spot on. The exhaust valve guide on the #3 cylinder was worn. Jon stated that the engine was still plenty safe to fly, but would continue to use more oil than normal.

So, what to do now? O-290 cylinders are rare and expensive. Lycoming hasn’t made them since the mid-60’s and the supply sure isn’t what it used to be. Well, what about shopping around for a used jug, or even another 290 all together? I realized that would be a reasonably cost effective alternative, and I even found a good engine for a good price in Saskatchewan.

But I also realized that I was merely delaying the inevitable. My 290 would have to be replaced, either in whole in part, sooner rather than later. Not a surprise, at all; in fact I’d planned for this since I bought the Cav in 2012.

My goal is to keep the Cav until I die or lose my medical, whichever comes first. Thus, the most enduring solution was to replace the 290 with a Lycoming O-320, probably the most commonly found piston aircraft engine on the planet. They typically have a TBO of about 2000 hours. I’d need one of the older variety, one with the conical style engine mounts to match the existing engine mount on the Cav. That meant a 320-A or B series engine.

I shopped around and settled on an overhauled O320-A2B from Vike Airmotive in Kamloops, BC. I bought an engine from Ken Vike for my Bushmaster a number of years ago with excellent results, so I had no trouble doing business with Ken again. Ken and his son Kyle are building the engine for me as of this writing.

Switching to an O-320 will be a double-edged sword. I wanted to stick with the 290D as it’s an outstanding combination of power, reliability and fuel economy. It hauls the Cav at an honest 110 kts or better, climbs very well even when heavy, and burns about 5.5 gallons per hour. But, as I’ve indicated, parts are hard to find. I have no desire to be stranded somewhere as an engineer tells me the part I need for my engine simply no longer exists, or is outrageously expensive to acquire.

By comparison, Lycoming O-320s almost grow on trees. Parts for them are everywhere and relatively cheap. Every engineer who’s worked on a Cessna 172 – and there are likely none who haven’t – is familiar with the 320 and knows where to get parts for it. So, if I am stranded, it won’t be for long.

The 320 will burn more gas, of course, but it also means more power. The Cav is light and climbs well on 125 hp, so with the 320’s 150 horses strapped on, it will climb awesomely. It means a change to the prop, too, of course. But I’ve already looked after that. I had Aero Propellers of Calgary twist the blades to meet O-320 specs.

A brief aside about the propeller: When examining the options surrounding what to do about a prop for the 320, my first choice was to simply have the 290’s prop twisted to a new pitch that would match the engine. Gord, at Aero Propellers said it could only be twisted up to 58″ of pitch from its current 54″. Diameter is 74″. I had hoped that I could get it pitched to 60″ because that’s what I read was the standard pitch (as opposed to cruise or climb pitch) for the 320 of 150 hp. Thus, I thought 60″ would be the standard pitch for all 150 hp installations. Not so.

Other charts I consulted showed that only 58″ was the standard pitch for a number of 150 hp Lycoming installs on planes like Piper Cherokees, Beech Musketeers, some Citabrias and even some C-172s. Sorting out why these standards might differ is way beyond what I’ve got time for, so I’m just happy I could get my prop re-adjusted to fit the new engine rather than having to get a replacement.

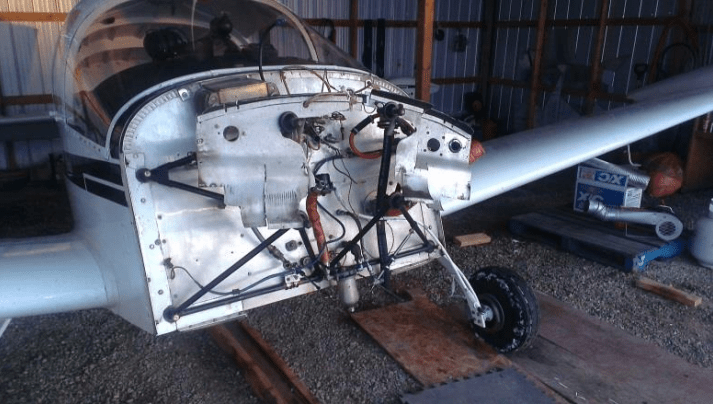

One very good thing about the 320-A2B installation is how it’s identical in all dimensions to the 290. Pull one out and put the other in. It’s a bit heavier, by maybe 20 pounds, but I’ve already made up for that by using a light-weight starter, and eliminating the vacuum pump and associated instruments to shave off nearly the entire weight difference. The CG will be nearly unaffected.

I hope to have the 320 in hand by mid-February. I’ll then begin the installation, which ought to take only a couple of days. As good a performer as the Cavalier was with 125 hp, I can’t wait to see how it flies with 20 percent more power. I’ll be sure to provide full details in an upcoming issue of Skywriter.