Welcome to November! It’s hard to believe that another year is nearing its end. For me, November is a time when I get to reflect on the past years flying as I fill out the insurance forms for renewal. For whatever reason, this year I spent much more time reflecting on my Christavia MK 1, affectionately named Chrissy, and how she has evolved for me over the years.

I originally decided to build a plane while attending university in Toronto. I spent much of my spare time poring over Kitplanes and other similar publications. My favorite was always the December issue when I got to see all the different plans-built and kit-built aircraft available. It was my “Christmas Wish Book”.

One aircraft that caught my eye was the Cygnet, and I was so enamored that I eventually bought plans. I spent hours studying the drawings but eventually questioned just how well it would perform on floats.

After I graduated, I took a closer look at another design that had interested me, the Christavia. While living in Toronto, I took a trip to visit the designer, Ron Mason, and look over the MK 1. There were three of them based on the field, and I liked what I saw. Having moved back to Newfoundland after graduating, the need for something capable of operating on floats was paramount. Newfoundland has only six airstrips and airports but thousands of lakes and ponds large enough to fly from (the nickname “The Rock” is quite inaccurate; “The Sponge” would be far more accurate).

I ordered plans in the fall of 1989 and immediately started building pieces. From the beginning, I decided that my freshly minted aerospace engineering degree should be put to the test, and I started modifying things. Some ideas proved to work well, and other ideas were eventually abandoned. For example, I had originally planned on adding flaps to aid in float performance but decided against the complexity when I flew a Citabria 7-ECA here in Springbank.

Some changes were cosmetic, like squaring the tail to resemble a Citabria, and others were more practical, like flipping the control torque tube upside down so it mounted under the floor rather than on the floor. The addition of flip-up windows on both sides of the plane was more of a romantic idea as it would allow for an open cockpit feel. This has worked out very nicely on those calm, warm summer evenings.

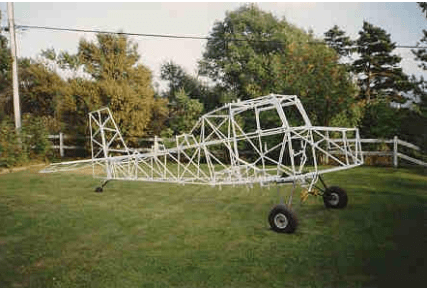

From the fall of 1989 to the spring of 1995, I worked sporadically on the plane as both time and money allowed. I was also flying the family’s Cessna 180, so spare cash was often used to pay for fuel rather than plane bits. However, I did manage to build my wing ribs (modified from built-up spruce to plywood), fuselage, tail, and landing gear.

One other thing happened in this time. I heard about and met another Christavia builder in Newfoundland. At the time I first met him, Steve Whitenect was an RCMP officer stationed in Pasadena, Newfoundland, which was about seven hours’ drive from my home in St. John’s. Any time I passed through, I made time to drop in and check on the progress. Steve completed his plane in 1992 and was relocated to Gander, much closer to St. John’s and only 20 minutes (by air) from my parent’s summer home. During one visit, I finally got to fly a Christavia. To this day, it’s the one and only flight I’ve taken in a Christavia other than my own. I was happy with what I saw and knew that I had chosen the right aircraft.

With my work on the Hibernia project winding down, I started job hunting and turned up an IT position in Calgary. Of course, by moving to Alberta, the primary mission of Chrissy would change radically. If you hadn’t noticed, there isn’t a whole lot of water out here to operate a floatplane, but there are hundreds of airstrips. What water there is around here has such a high elevation that float flying is impractical. Fortunately, Chrissy is at home on grass as well as she is on floats.

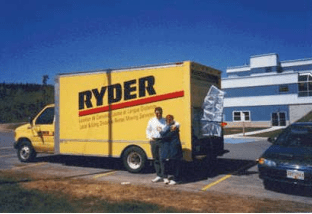

The move to Calgary was interesting in itself, with a Ryder truck loaded with all our worldly possessions, including the tail of the plane sticking out the back! Moving to Calgary meant giving up my father’s fully stocked workshop where Chrissy was incubating. I was fortunate to find a duplex that had a garage and an unfinished room in the basement, perfect to build airplanes in. Unfortunately, starting a new job, new life, and new marriage demanded much from the meager supply of funds and spare time, leaving little for building airplanes.

Chrissy languished until about 1998 when I decided to put a real push on finishing the plane. With a renewed vigor and help from my wife, Renée, Chrissy started to take shape with the wings being completed, the tail, fuselage, and landing gear covered and painted, and with a final decision on an engine.

Renée and I spent a weekend in Montana with Tammy and Paul Yednick, the couple that owned and operated Aircraft Finishing Systems (AFS). Another couple from Montana also joined us for a weekend of instruction in how to use this environmentally friendly covering system. AFS has since been sold to Steward Aircraft and is now marketed under the Stewart Finishing Systems moniker.

The choice of engine was hard for me. Over the building period, I bought a run-out Lycoming O-235, a Continental A-75, a Continental C-85, two Subaru EA-81’s, a VW, and a Franklin engine before settling on a second, factory-new PZL Franklin 4A-235-B3 complete with prop and baffles.

The exhaust was built by Acorn Welding in Edmonton. Rather than send a bunch of drawings back and forth, I simply bolted the engine and mount to the ¾” plywood form that had been used to make the firewall. That, along with the nose bowl, was hauled up to their Edmonton shop which allowed them to build a perfect exhaust system that fit nicely under the cowls.

The project came to another screeching halt in the fall of 2001 when we decided to buy a new house. Although the house had a great spot for a garage, none existed at the time. A friend offered me the use of his garage to store the fuselage, complete with engine, and I cleared out a large section of the basement to convert into a wood workshop where the rest of the airplane was stored. It took about four months to build my dream garage and provide power, heat, internet, cable TV, and the other basic amenities.

With 13 lights in the ceiling, Renée thought I was planning on doing a little surgery on the side!

With the garage built (the city would not let me call it a hangar as we live directly adjacent to a green belt that may be mistaken as an airstrip…), Chrissy came home. Now things were stepped up a notch as the wings were covered and painted, followed by the tedium of completing the never-ending list of small tasks. During this time, I joined the CRUFC and was introduced to Glenn Bishell. I decided to rent a hangar from him even though I was still a year away from completion.

Spring of 2004 was very exciting for me as everything came together on the plane. Tim Morrison from Stauffer came over and helped me inspect and pre-oil the engine in anticipation of the first flight. Glenn graciously provided his services along with his truck and trailer to move the fuselage to Carstairs. Most of the month of June was spent assembling the plane for the last time with lots of help from Glenn and Mike Sweare.

Early July saw the first run of the engine since it had been manufactured nearly a decade before. Everything went well, and after a few minor adjustments, it was ready to fly. John Moulder from Red Deer was assigned to me as my MDRA inspector. After a full day of inspections and paperwork, John had only found a couple of small snags that were easily rectified before he left for the day, leaving me with a fresh flight permit!

I was also preparing myself for the first flight and had flown with the late Doug Jenkins about 25 hours that spring in a Citabria 7ECA, including a number of circuits at Carstairs. I was feeling quite confident about making the maiden flight in Chrissy even though Doug had offered to do it for me.

July 5th was a beautiful day, and I had taken it off work to work on the plane. Just after lunch, I called Renée and told her I was going to fly. As she drove up, I was conducting some high-speed taxi tests. The only problem I encountered was that the toe brake pedals were too upright, and I kept riding the brakes during the taxi tests. A couple of 1” wooden blocks tied wrapped to the heel of the rudder pedals provided a temporary fix.

At long last, with Renée behind the camera, I made the first flight!!! To be honest, I found this flight to be far more memorable and exciting than my first solo flight! The flight was trouble-free with the exception of the electric turn coordinator popping its breaker. The plane did not fly right off the drawing board, though, and I noticed that one wing was heavy and that the oil temperature was high. After 15 minutes of flying, including some stalls, I brought her in for the first landing, which was also uneventful.

The next two months were spent tweaking some small snags and rigging the plane to fly straight. On August 25th, I finally finished the 25-hour test period and received the permanent Special Certificate of Airworthiness.

A lot has happened since then, and I now have 577.5 hours logged in Chrissy. I suspect that had I moved to Alberta before beginning Chrissy, I would not have built a Christavia. There are other aircraft that would have looked more appealing on paper than the Christavia when floats are not a consideration.

Fortunately, I did decide on the Christavia, and it’s a decision I’ve been quite happy with. Next month I’ll continue sharing my experiences with Chrissy since she first flew and how it’s evolved into the plane she is today.

I know many of you have had some interesting flights and adventures over the summer. Please consider writing an article to share those experiences with the club. Please forward any articles to me, and I will get them published.