The Machine Under the Man

My aerobatic dreams have come one step closer now that I have finally finalized the deal on my new plane several months ago. It has been a long road getting here with several missed opportunities along the way. The new plane, as many of you readers will already know, is a Sukhoi 29.

Before the Sukhoi I primarily flew a Cessna 172 while logging a bunch of time in a Citabria and a Super Decathlon. All these planes are great planes, but they just held me back from accomplishing what I wanted with aerobatic flight. Now there is nothing wrong with a Super Decathlon, for most people they’re great planes. I am not most people, seeing how I am 6’4” and 280lbs, so my desire for a solid 2 place aerobatic plane led me to Russia. My first interest was a Yak 54, but that deal fell apart for various reasons. Actually, I am quite glad it did as I now have a far superior plane, although in the same breath the Yak 54 was a whole bunch cheaper than the Sukhoi.

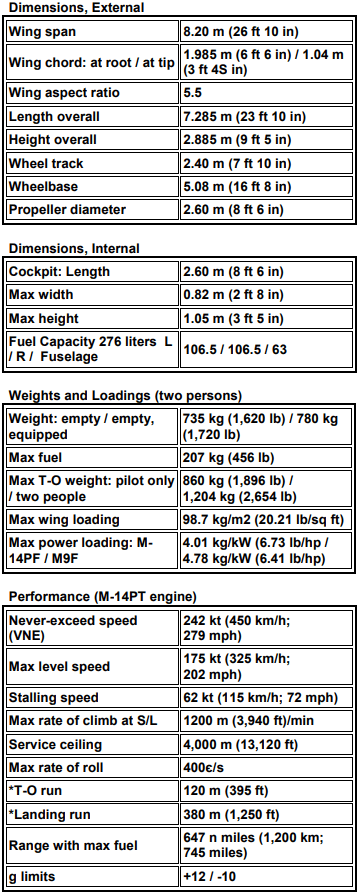

Seeing how this is my first try at what will hopefully be a regular article in the Sky Writer, I will start with some specs and some details about the Sukhoi’s and they’re history. In the future, if everyone wants to hear more I will move into more human based stories about my experiences with aerobatics and flying in general.

The former Soviet Union was always a country that put state before people yet within the government military ranks airplanes are named in some way after the men who designed or pioneered them. Engineers with talent were given the task of managing whole engineering teams and production facilities to make airplanes. A notable example is the “MiG” designation, which is short for Mikoyan-Gurevich, which in turn came from the last names of A. I. Mikoyan and M.I. Gurevich. These two fighter designers founded the world-famous family of “MiG” aircraft. In the case of the Sukhoi line, they were named after Pavel Osipovich Sukhoi. Sukhoi Graduated from Moscow Technical Aircraft University in 1925 and had a great hand in designing many aircraft. The Sukhoi design bureau produced the first Soviet supersonic interceptors before closing in 1949. It was subsequently re-opened by Pavel Sukhoi shortly after Stalin died. The experimental jet aircraft produced by the Sukhoi bureau set various world speed and height records. Pavel Sukhoi died in 1975 but even today the Su design bureau exists and continues to produce some of the best airplanes in the world.

In the early 80’s Russian superiority within the aerobatic circles started to falter. This prompted the commissioning of the Sukhoi design bureau to build a no holds barred aerobatic airplane. They were given a clean slate and a blank check to complete this task, the evidence of that is seen in the construction materials used and the building techniques employed in the first Su 26’s built in the early 80’s. The factory even stayed light on their feet throughout the entire run of airplanes, during production various changes were made to improve the design or repair deficiencies found during use. Later on, they added the Su 29 and the Su 31 to their line of planes. What they built stands even today as the benchmark for all competition aerobatic airplanes.

Sukhoi 29 Design Features

Two-seat redevelopment of the mid-wing Su-26M single-seat aerobatic competition aircraft, the wingspan and overall length was increased; they improved the aerodynamics and reduced the stability margin for enhanced maneuverability.

The wing leading edges have a sweepback of 3 deg / 28′; it has a specially developed symmetrical section that is variable along the span; symmetrical section thickness / chord ratio is 16 per cent at root and 12 per cent at the tip. It is also slightly concave in region of the ailerons to increase their effectiveness. The leading-edge is somewhat sharper than usual to improve responsiveness to control surface movement. The dihedral is 0 deg and the incidence is 0 deg.

Structure

Composites comprise more than 60% of the airframe weight, it has a one-piece wing covered with honeycomb composites panels; the front box spar is foam-filled with carbon fiber reinforced plastic (CFRP) booms and wound glass fiber webs. The channel section rear spar is also made of CFRP and the truss ribs are titanium. The ailerons are foam filled and have a CFRP box spar and a Glass Fiber Reinforced Polymer (GFRP) skin. The fuselage has a basic welded truss structure of VNS-2 high-strength stainless steel tubing. The lower nose section of the truss is removable for wing detachment. The fuselage skin panels remove quickly and are made from a honeycomb composite. The integral fin and tailplane construction are the same as the wings. The rudder and elevator construction are the same as the ailerons. The exhaust, battery box and firewall are all titanium. The engine cowlings are made from a light alloy. The control linkages are made from forged magnesium.

Landing Gear

The main wheel legs are a fixed arched cantilever made from titanium alloy. Hydraulic disc brakes are standard. The non retractable steerable tail wheel connects to the rudder with titanium springs, it is also lockable for take-off and landings.