Over the years, I’ve flown a number of different aircraft; some of it was logged and some of it wasn’t. Though the types of aircraft range from gliders to Dash 7s, I only had the opportunity to fly one ultralight, Wayne Winter’s Rotax 618 powered Merlin. On the other hand, the Cessna 150 has shown up numerous times in my logbook, including all my flight training for my Private Pilot’s License back in 1984 (when I was 24 years younger and 100 lbs lighter!)

Back in November, Jamie Hepfner from Springbank Air Training College called to make me an offer I could not refuse. They had recently become the dealers for the Flight Design CT and wanted me to do a flight review for our Skywriter in exchange for a flight in my Cessna 150.

The CT is a composite, high-wing, two-seat design that sports a tricycle landing gear and an electrically actuated carbon fiber prop mated to a 100 HP Rotax 912S engine. Obviously, it’s difficult not to compare this plane against the venerable Cessna 150, so I decided to present this review as a comparison between new and old, the CT and the Cessna 150.

Although we first discussed the article in November, it wasn’t until February 10th that all the stars aligned to allow for the flight. Through January and early February, I had been flying at Springbank Air Training College trying to finish off my Commercial License. Troy Ritchie is one of the senior instructors I’ve been flying with and agreed to accompany me on this flight.

The first thing you notice as you approach the CT is the almost comical appearance of the aircraft. The fuselage has a bulbous, egg-shaped forward section that tapers to a tube-like boom that supports the thick, but otherwise small tail. The cowling and prop look impossibly small for such a large cabin, and the landing gear has a very small track and wheelbase. The second thing you notice is just how smooth and aerodynamically clean this design is. Everything fits flush and has a mirror-like finish. Wheels and brakes are nestled under tight-fitting fairings, and the gear legs are also aerodynamically faired.

By comparison, the C-150 has a relatively stock look to it. Except for the tall, upright windshield, it has very indistinguishable looks. Let’s face it, the C-150 and C-172 make up a very large chunk of the aircraft flying in Canada and the US and have become what the general public expects to see when looking at a light plane. Compared to the CT, the C-150’s lines are anything but smooth. Hard lines define the edges of the windshields and tail group. Rivet heads cover the plane, and most C-150s lost their wheel fairings years ago.

Performing a walk-around is pretty straightforward on the CT and surprisingly similar to the C-150. About the only addition is checking the coolant level. Both aircraft allow only a small access door for checking the health of the engine. Flight Design has made it possible to do a far more thorough job of inspecting the plane. Clear material is installed in the wing below the aileron bell cranks allowing for a visual inspection of these critical components. Also, removing the cargo bay covers behind the main doors allows for visual inspection of the main gear attachment point.

At this point, it’s worth comparing the cargo areas in the two aircraft. The C-150 is the clear winner in this category, with a cavernous space behind the two front seats with four cargo tie-downs to help restrain the maximum 120 lb load. The CT has a smaller space behind the seats that is not accessible from the cockpit and is shared with the main gear attachment structure and the ELT. However, it does have two large exterior cargo doors to access this space. The CT also has two cubbies under the floor ahead of the seats. These are also difficult to access in flight as they are situated under your knees and ahead of the stick. The C-150’s glove box and seat back pockets provide a more useful storage area for things like maps and flight supplements. The CT we were flying is an older 2004 model. The new 2007 CTSW does have an additional pocket between the seats and pockets in the doors.

The CT has a clear advantage when it comes to accessing the cabin. The two large doors have top-mounted hinges that fold up out of the way under the wing. That, along with a lack of struts, makes getting in the CT no more difficult than getting in a compact car, with the exception of having to maneuver your inboard leg over the stick. Once seated, with the door closed, you quickly realize that although this is a small aircraft, the cabin is HUGE. Troy and I were barely touching elbows, which is amazing considering that I’m 6’0” and well above the 200 lb mark, and Troy is about 5’10 and 180 lbs. In the C-150, you had better like your passenger as you will be very intimate with him or her by the time you land!

Seat adjustment can be accomplished while seated in the CT, but it wasn’t easy. The seat does not move as easily on the track as you find in a typical Cessna. However, the biggest drawback with the CT was the shoulder harness. There was no way I could wear them as they were simply too short. Considering that the main spar for the cantilever wing passes through the cabin right in front of your noggin, shoulder straps are a necessity. However, the lap belt fit fine. This is something that should be addressed and hopefully has been in later models. Of course, my 1968 C-150 was not equipped with shoulder straps when it left the factory, but like most C-150s, they have been retrofitted into the cabin and pose no difficulty even with my XXL dimensions.

The CT is not equipped with differential braking. Instead, it uses a large lever to the right of the center console to apply even braking to both wheels. This seems to eliminate the need for a “pedal.” Instead, there are simply two horizontal bars to rest your feet on and control the rudder. I found that these bars sat too low for me to comfortably actuate them with my size 13 feet! One annoying feature that has been fixed in newer models is the park brake. The brake lever needs to be fully engaged with one hand, while reaching across with your other hand to flick the knob that locks the brakes. Although the braking proved effective and there was more than ample nosewheel steering, I still prefer the “normal” differential toe braking provided in the C-150.

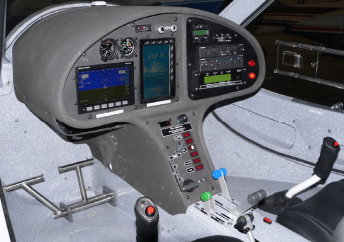

Our CT was equipped with a large screened Dynon EFIS system with a backup altimeter and airspeed indicator. A King KY 97 transceiver and a transponder provided communication with a large Skymap GPS completing the panel. The flaps are controlled by a rotary switch at the top of the center console with a digital readout providing position. The desired flap position will flash in the display while in transit. Below that is the keyed ignition switch. The fuel cut-off lever is a large control located on the left side of the upper center console. The carburetor and cabin heat controls are at the top of the panel, with the remainder of the secondary controls located on the lower part of the console. This area gets pretty busy with trim, choke, throttle, and brake levers located side by side on the 6” wide console. One last lever is located behind this cluster and is used to select the pitch of the electrically controlled propeller. This lever takes a little getting used to. It has a safety catch that you lift while moving the lever. The catch fits into detents that provide the pilot with a fixed number of settings. Unfortunately, my wide posterior easily detected the position of the lever as it progressed into the coarser positions. Overall, the controls, although functional, do take a bit of use to get comfortable with.

One pet peeve I had was the lack of labels on some of the controls. I would like to have seen the flap settings noted under the rotary switch and the ignition switch functions labeled on the keyed switch.

By comparison, the C-150 has a relatively well laid out panel with familiar throttle, carb heat, mixture, flap, and trim controls. Of course, having flown Cessnas for a large chunk of my flight experience, it’s not surprising that I’d feel more comfortable with this layout. Had I learned in a CT, I’d likely be complaining about the C-150’s layout. There is nothing about the CT’s cabin and controls that I wouldn’t feel comfortable with after a few flight hours.

Finally, time to light the fires. Although it was -15° C, the plane had been sitting in a warm hangar prior to our flight. The engine started easily with the use of the choke. Once running, the choke was adjusted until the engine ran smoothly. The first thing I noticed as we started to taxi was how easy the plane was to steer despite not having differential brakes. However, that didn’t keep me from trying to activate the non-existent toe brakes. The run-up was simple with only mags to check. The prop was set to full fine and the flaps to 15° for take-off. As the power came up, there was a satisfying acceleration rate, much greater than the C-150. We were off the ground in less than 500’ with a very positive rate of climb. As we climbed out, the prop pitch was brought back one notch, then the flaps were set to 0°, then another notch of pitch, then the flaps to NEGATIVE 12°, then another notch of pitch. The object here is to keep the full-throttle RPM between 5000 and 5200 by using the pitch control.

With the plane set up in climb, I finally had a chance to look at the EFIS and check out the performance. We were climbing at 80 knots, about 10 knots faster than the best rate of climb speed. Despite that, we were showing a solid 750 fpm at just under the 1232 gross weight. This gross weight is used for Canadian registered planes in the AULA category, while 1320 lbs is used in the US under the LSA category. The impressive climb rate had us at our assigned altitude of 5500’ in about 2 minutes. This plane is a rocket ship compared to the marginal 300-400 fpm normally seen at our elevations in the C-150! The CT is a plane I’d have no reservations taking on a mountain trip… not so with the C-150.

Cruise flight was next. Given our altitude, we left the throttle at full, which should provide about 75% of sea level power. The prop pitch was adjusted to maintain our 5000-5200 RPM. Once everything had stabilized out, a solid 110 knots cruise was observed. This plane will outperform the C-150’s 85-90 knots cruise in spades and even has an edge on all but the newest C-172s! The view is outstanding with the low panel and low side windows. The slightest bank and you’re looking directly down! Despite lacking the rear window of the C-150, the nod goes to the CT for visibility.

Next, we started in on some maneuvering. The CT is VERY responsive in both pitch and roll, much more so than the C-150. However, Flight Design has given the CT’s controls a much heavier feel than the C-150. This prevents new pilots from over-controlling. Unfortunately, I found the controls to be unbalanced. By that I mean that the ailerons required almost twice the force for the same deflection as the elevators did. Although it doesn’t hamper the performance, it did feel a little awkward. The C-150 does have a more balanced control feel despite being less responsive. Despite that, I still prefer the CT in this category.

The stall on the CT was VERY docile. Essentially, it wasn’t much more than a nose-high rapid descent with full control maintained. This is great for personal use, but probably less so for training. Students should see how the stall typically develops and breaks as part of their training. The stock C-150 breaks normally in the stall. However, I’ve installed VG’s on my C-150 which dramatically lowers the stall speed without changing the break.

Finally, it was time to head home. As we headed in, the tower advised a Super Cub to “watch for an overtaking Ultralight high on the left.” Boy, did we ever overtake him! He looked like he was standing still, and I’m sure he was cursing for having been so thoroughly beat by an ULTRALIGHT!

Lowering visibility due to snow squalls prevented us from doing circuits, but the one landing I did do was quite interesting. The plane is very clean, which becomes very obvious while trying to slow down and descend in the approach. With idle power, full flaps, full fine prop pitch, and a slip thrown in for good measure, I still couldn’t descend much more than 700 fpm. A C-150 would drop like a stone in this configuration! However, I was able to plant it on the first half of the runway. Using brakes, I was off on Alpha.

As an aircraft for personal transportation, the CT has a lot to offer: high cruise, good visibility, modern avionics, comfortable cabin, adequate baggage storage, and unique styling. The biggest hurdle with the CT is the price tag that runs well north of $100K. Comparing this plane against a 40-year-old C-150 probably isn’t that fair unless you look at its original 1968 price tag of $9,550. Based on the Bank of Canada’s inflation rate, that same plane should cost $56,562 new in 2007. Ok, so that’s not altogether fair either, as Cessna did produce some 3000 copies in 1968, and there are certainly efficiencies gained when producing aircraft in that number. Basically, the CT is light years ahead of the C-150 in almost every way but one. The C-150 remains one of the leaders in cheap flying!

The CT may find it hard to compete with other aircraft available to the private pilot as it’s solidly in the price range of a good, used Cessna 182. If you want a new, two-seat design, Ralph Inkster could build you an RV-7A in the same price range that will outperform the CT in almost every way. However, the operational costs after the purchase will be far more palatable in the CT than either of these options. If you’re in the market for a new, factory-built ultralight, the CT provides excellent bang for the buck!