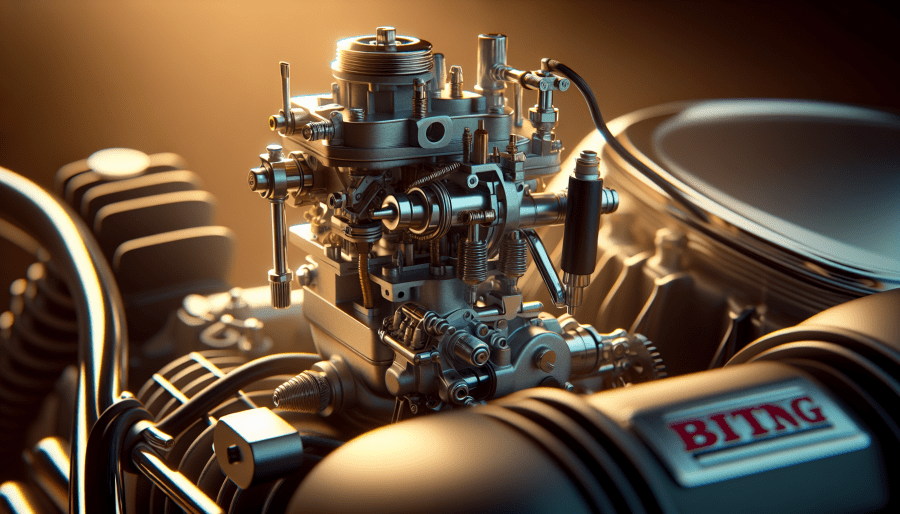

For those of you who didn’t attend your March meeting, and missed the CARB Clinic, here Is some information on the Bing carb used on Rotax Engines. For those of you who attended the meeting, this will be a reference and reminder.

The most common problem I hear about is mid-range hesitation. You are on final and appear to be a little high and a little fast, but canyon until at 50 feet you have burned up half the runway, so decide to go around. You Jam the throttle ahead and nothing happens. This scenario should not be allowed to happen and the following is the solution.

Understanding how the slide carb works, I think is important So here Is what happens. The right air/fuel mixture at any throttle setting is very important to your engine. As well as fuel to burn and oil to lubricate Is also part of the process of proper carb setting.

Your carb has to provide various mixtures of fuel/air at different R.P.M’s, for Instance – at idle about 1 to 10, at full throttle about 1 to 16. This is accomplished by three separate systems In the carb. First, the pilot system or idle circuit as we call it is Auto-carbs. This consists of the pilot Jet – a fixed Jet to meter the fuel and an air regulating screw or air mixture screw. This circuit affects the air/fuel mixture from idle to about 1/4 throttle.

Automobile carb idle mixture screws adjust fuel, whereas on Bing carbs it is an air adjustment, so think the opposite. Turning out makes the mixture leaner and vice versa. To set this adjustment, first, be very careful, engine must be running, turn the mixture screw (small brass screw next to the large idle speed screw) in until the idle is rough, then slowly tum out until the idle is smooth. It helps to watch your tachometer to set this adjustment.

The next circuit we will call “mid-range”. from 1/4 to 3/4 throttle. This is controlled by the jet needle and the needle jet. Confused? The Jet needle is a needle and you guessed it, the needle jet is a Jet. The jet needle is attached to the shoe valve or piston as Rotax calls it. As the throttle is opened, the needle rises out of the Jet and allows more fuel to slip up and past the tapered needle, where It mixes with air being sucked into the cylinders. This needle has three adjustable positions (3 grooves and a clip). With the clrcllp in the top groove, the needle is late rising out of the Jet which gives a lean mid-range, and the opposite if the clip is in the lower groove. With variable needle tapers and different-sized holes In the Jet, infinite adjustment is possible. BUT, you can make your mid-range work with the parts you have now.

Back to that hesitation on overshoot. You must determine if your hesitation is from too much fuel or not enough. The easy way to determine this requires you to have access to your choke. It can be done on the ground and that’s what I meant at the beginning when I said “It should not be allowed to happen”.

Standing with access to throttle and choke, with aircraft tied down and wheels blocked. Warm the engine and leave it idle for 20 – 30 seconds, then accelerate smoothly but quickly. If the speed doesn’t pick up right away add choke with the throttle at full open. If the engine continues to bog, it is too rich already and the needle needs to be lowered. If the engine picks up, it is too lean and the needle needs to be raised. If a full adjustment in one direction doesn’t cure the problem entirely, you might look for other possibilities: such as air cleaner restriction, float level too high, etc. If everything else is O.K., then you might consider a different jet and or needle.

The third system is the main Jet, from 3/4 to full throttle the jet needle is all the way out of the needle jet, and right below it Is the main Jet. A brass Jet with a pre-determined hole in it allows the right amount of fuel to supply the engine with the correct air /fuel mixture for maximum R.P.M. and power. The main jet supplied with your engine should be the right one for altitudes of O to 6000 feet. If you encounter density altitudes of over 6000 feet, your engine will run a tad rich, but rich is better than lean. I recommend you don’t change your main Jet unless you have a definite rich problem at full throttle, as would be indicated by the spark plug colour. Black is not beautiful, but very rich. Other problems cause richness at full throttle, so be careful in your decision to change your main jet.

I said there were three systems and each one uses another system, the slide valve. At idle, the slide is all the way closed, well almost, it is resting on the idle adjustment screw, which raises It a little. You old U.C. pilots (old, as in experienced) remember cutting a little square notch out of the slide, this allowed a little more air/fuel mixture to get by the closed shoe valve for idle, and is still found on the new carbs of today. As the throttle is advanced, the valve opens and allows more air to pass through the venturi, which in turn picks up more fuel. The problem usually found with the slide valve is a travel problem, not opening all the way. To check. open the throttle to fully open with the air cleaner removed, stick a finger in and up under the slide valve, and push up, the valve shouldn’t move, if it moves up – your throttle lever cable system needs adjustment. The other misunderstood part of the Bing is the choke circuit which is not a choke system, but an enrichening system or a “make it richer to start” device, the same result as a choke, but instead of starving or choking the air, it provides more fuel. When the engine Is cold, the fuel will not vapourize as quickly and therefore needs more to work with.

The other area of misunderstanding is the vent tubes. These must not be changed as tube length change could siphon fuel out of your float chamber and cause a lean condition, and you all remember about stir fry. The other adjustment possible is the float level or fuel level in the float bowl. By running your engine, stopping, removing the fuel line from the carb, putting your finger over the inlet fitting so the residual fuel can’t flow into the bowl, removing the clamp and bowl carefully, and noting the level of the fuel. This level should be between 1/2″ and 9/16″ from the top of the bowl. By very gently bending the little brass lever that rests against the needle valve, you can set your float or fuel level. Too high a level can cause wandering R.P.M. at a given throttle setting. Although this wandering problem may also be a tuned exhaust problem which we don’t have a solution for as yet.

I hope this information helps you to keep your Rotax running perfectly. If not. feel free to call me for advice.